© © 2022 Copyright © Youibot Robotics Co., Ltd. All rights reserved.SitemapPrivacy Policy

【Original】Breaking the "deadlock" of the semiconductor industry

Youaizhihe | semiconductor The article comes from: Gaogong Robot Network

2021-09-17 10:58:16 Reads: 1169

Summary"Under various stringent requirements, there are not many domestic mobile robot companies entering the semiconductor industry.”

Written by Zhang Haocheng

Affected by tense international relations, epidemics, and natural disasters in the past two years, the global semiconductor production capacity has been insufficient, and my country's semiconductor supply has become more and more serious. The continuous outbreak of the market has further increased the demand for chips in my country.

As the shortage of chips is further highlighted,Chips have become a "strategic material" as important as oil , the expansion of the semiconductor industry is imperative, and new efficient smart factories are urgently needed.

In this context, "High-tech Mobile Robot" interviewed Huang Jianlong, general manager of UAI Zhihe Semiconductor Automation Division, to discuss the current difficulties in expanding production in the semiconductor industry and the opportunities for mobile robots in it.

challenge

Super-large workshop, strict production conditions, more than 1,000 production processes, compact production tasks, frequent loading and unloading and transportation of various materials, close coordination between people, equipment and various systems, How to effectively transfer to make production safe and efficient?

This is also Production difficulties faced by the expansion of the semiconductor industry, especially the expansion of wafer production .

First, compared with traditional industrial scenarios, the production conditions of the wafer workshop are harsh, and the cleanliness requirements reach CLASS100 level, and some processes even reach CLASS1 level. At the same time, during the transfer process, the wafers are very precise and have strict requirements on static electricity and vibration. In the manual transfer process, jitter and rough operation are inevitable, which can easily lead to a decrease in product yield.

Second, due to the high density of wafers, the weight of a single wafer box can reach 5-10kg, and due to the requirements of cleanliness level, etc., workers need to wear protective clothing wrapped all over the body to carry out high-intensity handling work all day. Severe loss of personnel . At the same time, most of the operators in the factory are women, and the problem of high work intensity has become more prominent, and employment has become an increasingly difficult problem.

In the past two years, some semiconductor manufacturers have extended their recruitment scope from their provinces to central and western regions such as Gansu and Yunnan, but have not achieved good recruitment results. At the same time, the turnover rate of employees continued to rise. A senior executive of a fab told the "High-tech Mobile Robot" that one of their factories Field operator turnover rate above 70% in 2020 .

Third, most of the wafer production processes are completed by special equipment, but The data between the equipment in each production link is discrete, the production material information cannot be tracked, and the production rhythm is seriously affected .

new species emerge

在过去,晶圆厂转运用到的“物种”是 Crane system,通过“吊顶”的方式将晶圆从空中进行转运,其 The deployment is difficult and the engineering cost is high At the same time, it is necessary to stop production during the construction process, which is not a cost-effective choice for enterprises.

In such a case, Mobile robots are in the sights of fab manufacturers .

Mobile robots are used in wafer production. They can effectively transfer materials in the production process, and can complete operations such as loading and unloading. At the same time, they can work continuously for 24 hours, and their cost is significantly lower than that of the crane system.

but There are still many limitations for mobile robots to be applied to wafer production.Huang Jianlong pointed out: "It is not easy for mobile robots to enter the semiconductor industry, and there are many difficulties. Mobile robots must fully consider the characteristics of the semiconductor industry, not only to meet the requirements of hard indicators such as cleanliness, but also to provide robots that are intelligent enough. It can make production more flexible, effectively ensure yield and increase production capacity.”

Specifically, first , Due to the characteristics of the industry, the cleanliness level of the mobile robot itself needs to be at least CLASS100, and the vibration of the body needs to be avoided as much as possible.

Second,

The numerous processes and centralized equipment layout lead to the need for mobile robots to perform frequent and repeated transfer work between processes, which also requires mobile robots to "walk fast" and "accurately", that is, they need to be fast enough and stable enough speed and positioning accuracy down to the millimeter level.

At the same time, mobile robots also need to take into account operations such as loading and unloading, and must have "bright eyes" and "flexible hands", that is, a reliable visual positioning system and an end effector that can effectively perform grasping actions.

finally , the most important task for mobile robots to enter wafer production is to increase production capacity, which requires mobile robots to ensure a stable production cycle.

Huang Jianlong said:“ Under various strict requirements, there are not many domestic mobile robot companies entering the semiconductor industry.”

Youai Zhihe is one of the companies with excellent "record". After continuous polishing of products, Youai Zhihe's mobile robot has reached the leading level in the industry. The cleanliness level can meet the requirements of CLASS100, and the vibration value is the lowest when moving at 1m/s. Up to 0.04G, far lower than the SEMI standard 0.5G.

In wafer production, UAI Zhihe takes smart industrial logistics as an entry point, uses mobile robots as a physical connection device, and adds a smart logistics system to it, making it an infrastructure to help open up on-site information and optimize production .

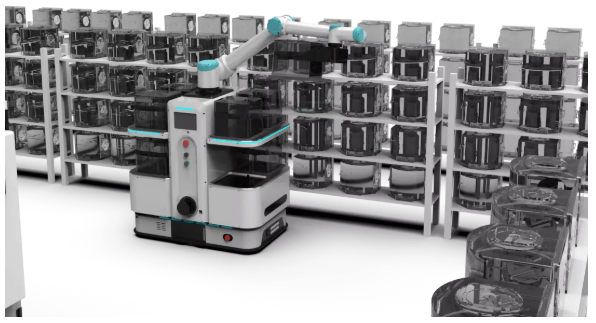

In terms of hardware, Youaizhihe has built a composite mobile operation robot for wafer handling, which can not only complete the transfer of wafer cassettes between various equipment in the factory, but also complete the automatic loading and unloading from the line warehouse to the production line, completely opening up Material flow from warehouse to production line.

In terms of software, the YouiTMS on-site logistics management and control system of Youaizhihe adopts order and waybill management, has both manual cross-platform operation and dual input ports for system docking, and is also equipped with a unique artificial intelligence algorithm. Many information flows, open up the data islands of each production link, establish a closed loop of logistics information in the product production process, and integrate enterprise MES, ERP and other application systems, which can effectively ensure the optimal efficiency of the production process.

landing speed

At present, Youaizhihe's compound mobile operation robot has reached cooperation with many top companies in well-known semiconductor factories at home and abroad, and has accumulated rich application cases.

Take the loading and unloading solution provided by Youaizhihe for a wafer factory as an example . The solution is equipped with multiple Youaizhihe wafer cassette handling robots and equipped with YOUIFLEET scheduling management system and YOUITMS logistics management and control system to effectively complete the automatic loading and unloading between the machine and the electronic material rack and the whole process of workshop logistics data. Refinement management , to achieve flexible and intelligent production in the wafer workshop.

In terms of effect, the solution realizes the precise loading and unloading of wafer cassettes, saves more than 60 manpower, reduces the risk of pollution in the clean room, and improves the yield; the cleanliness level can meet the requirements of Class 100 environment; avoid The damage caused by manual handling, the minimum vibration value when moving at a speed of 1m/s is only 0.04G, which is far lower than the SEMI standard of 0.5G; it reduces the operator's ineffective walking by 30%; improves the utilization rate of electronic material racks by 66%; , the whole plant production efficiency increased by 2%.

Huang Jianlong pointed out:“ With the current mobile robot solution of Youaizhihe, one mobile robot can complete the workload of 4 operators, and the return on investment period is within 2.63 years, and with the continuous increase in labor costs, the return on investment period continues to shorten. .”

With the continuous research and analysis of the industry, the technical advantages of its own software and hardware products, the service ability to respond quickly to customer needs, and an advantageous return on investment cycle, Youai Zhihe has quickly established barriers in the semiconductor industry, and the field provided Intralogistics solutions have been widely adopted by domestic leading semiconductor companies. At the same time, Youaizhihe's products have gone abroad and competed with foreign first-tier manufacturers on the same stage.

"In the past four years, Youaizhihe has become the leading company in the field of logistics solutions in the semiconductor industry. So far, although our focus is still mainly on fabs, we have also successfully deployed silicon wafers, packaging and testing, etc. Chip industry. We look forward to working with more partners and industry experts to explore the future of on-site logistics for mobile robots in the semiconductor industry, so that mobile robots can help the semiconductor industry develop better,” said Huang Jianlong.

By continuing to use the site you agree to our privacy policy Terms and Conditions.